Aswan Quarry and the Unfinished Obelisk Scoop Marks

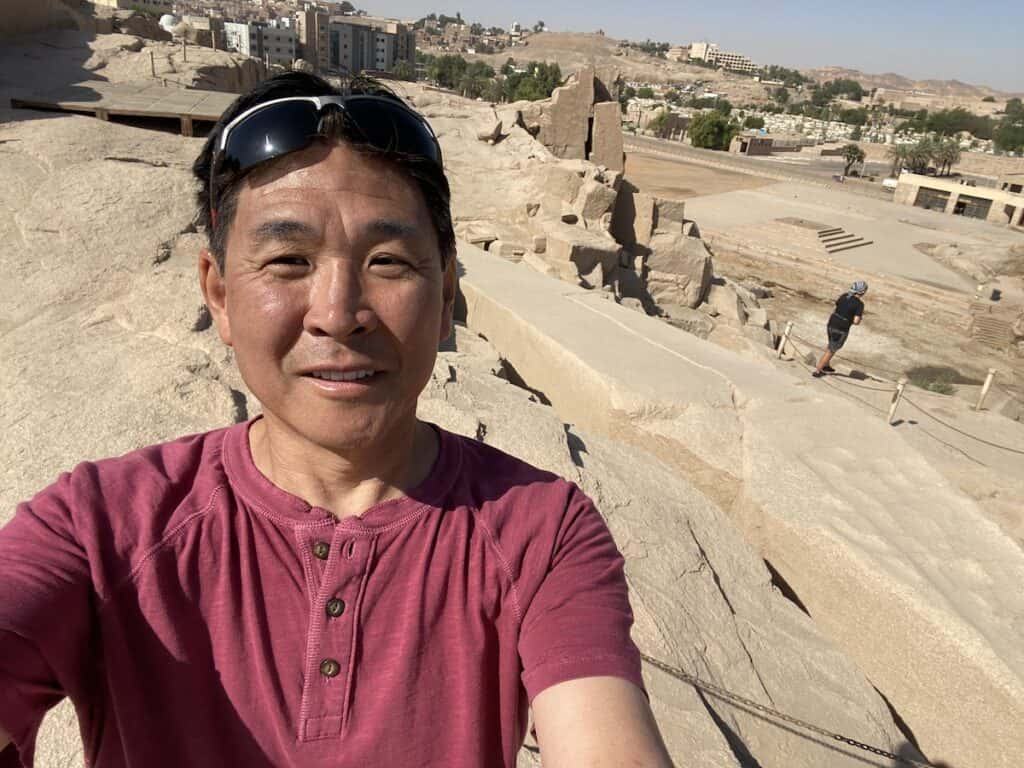

Mon, Oct 25: Aswan, Egypt

Welcome to the Aswan Quarry. Home of the 1,200 ton Unfinished Obelisk and the scoop marks. The story is, that a cracked formed while they were cutting it out so they abandoned it. One of the few times in history that we celebrate a job NOT done.

It’s stunning to come here and and imagine all the rose granite obelisks, large blocks, and the rough cut multi-ton statues that were quarried, then transported hundreds of miles away. This goes way beyond copper chisels and dolerite pounders. Surely there was a far more efficient way to quarry stone. Enter the scoop shaped tool marks.

TIP: Be on the lookout for hand sized, dark gray, dolerite stone pounders around the quarry. Try your luck at quarrying granite and see how realistic that theory is.

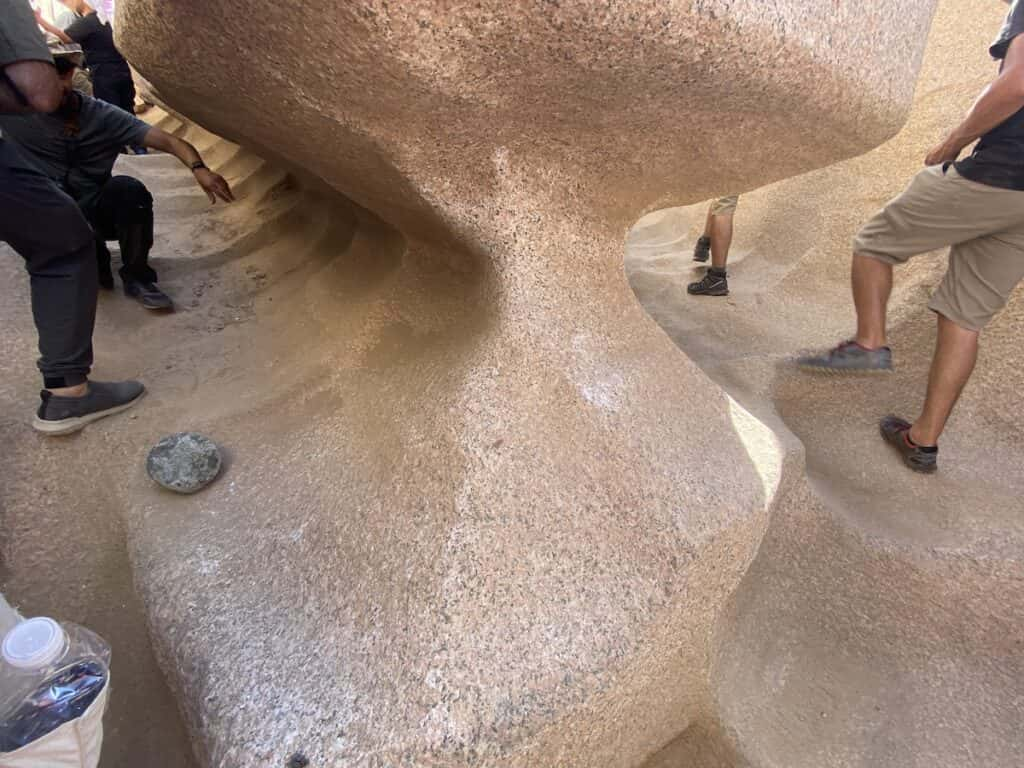

What are the Aswan Quarry Scoop Marks?

Someone sure went crazy with a scooping machine at the Aswan Quarry. What scoops granite like butter? I have no clue, but there are many examples of these scoop marks, and they are far too evenly sized to be made by hand.

One thing for sure that doesn’t leave scoop marks in granite; those dolerite pounding stones. Some archeologists claim that these stone pounders could be used to quarry and shape granite. We put that to the test in the video at the end of this post.

What caused the Aswan Quarry scoop marks?

Today, nobody knows what caused the scoop marks around the unfinished obelisk. Engineer Christopher Dunn suggests it was a machine with a pivoting arm that could scoop under the obelisk. Brien Foerster thinks it was vibrational technology. Some archeologists say it was the dolerite pounding stones.

If you visit the Aswan Quarry, it doesn’t take much critical observation to see that the scoop marks were not caused by dolerite pounders. We can agree that the scoop marks was caused by some lost ancient technology.

My theory: We don’t see any of the scooped granite around. That suggests it was not actually scooped by rather broken-down by a tool that left a scoop-shaped trail. That would be consistent with a rotating cylindrical-shaped tool. And I’m going to say it was powered by the device referred to as the Djed pillar.

The unfinished obelisk has scoop marks?

Yes, in the following photo you can see that there are scoop marks on the unfinished obelisk itself. The scoop marks actually go around and under the obelisk as well as in the surrounding bedrock. It’s almost like the granite was softened like butter and scooped out with a shovel.

Also notice all the scoop marks on and around the obelisk.

If you liked the unfinished obelisk, you’ll want to check the unfinished T-shaped pillar at Karahan Tepe, Turkey.

Additional photos from the Aswan Quarry from the UnchartedX Egypt Tour

Could stone pounders quarry granite in Aswan?

No. One of the common mainstream theories is that dolerite stone pounders were used to quarry granite. There are a bunch of these stone pounders in the quarry that you can use to test your strength and skill. I tried my hand at stone pounding, and here is the result:

From this simple demonstration, you can easily see that dolerite pounders could not accomplish anything other than some fine-tuning of granite surfaces. Certainly they are not responsible for all the Aswan Quarry scoop marks.

Some have shown that you can increase the effectiveness of the stone pounders by heating the underlying granite with fire. While heated granite does give way at a faster rate, the question is if it is a meaningful improvement.

What to do after quarrying a multi-ton obelisk?

The Aswan Quarry is just the first step. Even if you are able to figure out the scoop marks and determine how a multi-ton obelisk was quarried – including the final bit of separating the obelisk from the bedrock without getting crushed to death.

There is still the issue of moving the obelisk to its final destination hundreds of miles away. And not just once, as there are hundreds of them all over Egypt. Did they move the obelisks with ropes? How thick, how strong, and how many ropes would it take? So many questions..

There’s more mysteries to explore at the nearby Temple of Horus and Temple of Sobek.

Want more on quarries?, here’s a wiki on other Aswan Quarries.

How do you think the Unfinished Obelisk in the Aswan Quarry was shaped? How do you think you’d do with a dolerite stone pounder? Let us know in the comment section below.

Part of the Ben UnchartedX Egypt Tour

Why did you smack the two rocks together? That makes no sense. Do those scoop/ripple marks look like they were created by bumping rocks against each other!!?? Next time try rubbing the dolerite against the granite in a smooth forward-backward motion like you’re trying to create a single ripple from the pattern beside the obelisk. That’s a pattern created from repeated rubbing… not striking.

Thanks for the comment. Striking rocks could shatter / chip the granite which would be faster than sanding, particularly if as some have claimed, that fire was used to weaken the granite. Either way though, it would seem they would’ve used some sort of mechanical leverage to increase the striking or rubbing force.

I know how it was done and will tell you for 1 million dollers

I know how they cut the stones and once i tell the most obviouse answer i whant to be paid first

Very cool pictures, I had no idea this place existed. To me those scoop marks look a lot like some sort of tire tread. Don’t ask me how that could have happened!

Thanks! Yes, the whole quarry is weird. It’s huge. Scoop marks everywhere, and smooth deep holes, too.

I have looked at this for years , and it looks to me like framing with a sagged roof material that sagged around the framing. Look closely at the spacing, Its all pretty consistent

i have checked and its about 15 inches ridge to ridge. Thats about the same distance as modern house framing. also the vetrical lines in the trench , line up perfectly to the high ridges on the top. perhaps these were built before a muddy flood came and filled the interior buildings or structures with mud, the roof sagged and the are hardened and petrified.

Coming from a construction background and if it were mine to do:

I would use a mechanical pounder similar to a modern large hammer drill or pile driver. I would imagine that the tooling was something of this sort and that it/they pounded the squarish holes down into the granite several inches at a time before being moved to adjacent spot. I would argue that the “steps’ seen in the trench represent the tool “drill” depth and that the tool had to be moved frequently and sequentially. The tool head was likely of that harder stone and I would imagine they wore out quickly and required frequent replacement as evidences by the rough size difference in the marks. Cubic tools for reciprocating pounding would create the desired trenches.

The wear pattern also suggests a squarish pounding tool where the corners of the tool-head wold have worn down the quickest, followed by the sides, then the center where the material is the most supported from all sides. Modern square edged chisels always wear into a rounded shape.

I would also run water directly to each cutting head, while adding an abrasive grit as a cutting or grinding agent.

The power could be by hand by crew, but I would rather build a dedicated water pumping station, driven by river flow to pump water up to the site, the gravity energy of the pumped water outflow could then be harnessed through a water wheel or something similar to drive reciprocating tools, as a lubricating coolant for the tooling, and as a flushing medium.

This site I imagine, would have been fully rigged with scaffolding, substantial timbering and masts, rope work and blocking to support, guide and move the cutting machines, and to affect the removal of the rough blocks. Wood and any metals would have been stripped out or scavenged away.

I think the “test pits” are rigging mast mounts and would have enabled the lifting and the skipping or sledging of the blocks. The idea of test pits is dumb to me and would be a waste of time on a job-site. with stone that hard, everything is there for operational purposes.

To me, the “test pits” within the trench are either rigging mast mounts for lifting or, sump pits for pumping out wastewater and cutting fines, or maybe both – pomp pits while cutting and then mast pits to aide or guide lifting.

the undercuts suggest either a rather compact cutting machine or a levered, offset cutting head. I would imagine it to be a different tool or a tool head attachment.

In my view, this was an advanced, industrial operation to where I can see many drill machines and crew shifts running 24/7 to supply stone.

The little round balls I think would have been used for the secondary surface finishing operation and possibly as bearings for moving blocks, although wooden roller dowels would be far more effective and non-damaging. I would think too that the stone balls are themselves just worn out hammering stones, which started out more angular.

Thank you. This is excellent analysis which explains the tool mark artifacts that we see today.

Hand pounding is too ineffective, so some form of mechanical leverage would have been necessary. The “rigging mast mounts” make sense. Such a machine would need solid support.

A squarish cutting head explains the consistent sized and shaped scoop marks. Again, perfect sense, and fits the machine theory.

The machine powered by water theory is sound. There is the Nile river, which was used to transport blocks away is just 1 km (.5 miles) away from the quarry.

For the undercuts, it seems like they would use the same machine as the same force would be necessary. Some angled or levered block would be needed to redirect the force sideways.

Those scoop shapes could be due to a smaller diameter but long pole with the fulcrum point maybe a foot or two off the surface. The fulcrum point would be a hole in a plate, thus allowing the pole to move in 2D. The cutting end of the pole might have a hard stone attached. Weights would be added to the pole to put a heavy downward force on the cutting end. Workmen would push and pull the pole using the leverage gained by the low fulcrum. Most cutting would be in the X direction — back and forth, and then moving in the Y direction a bit and repeating the X scoring.

The scoop shape would result from the pole cutting weight reducing the farther the pole was off the vertical.

This is different than sanding in that it is a relatively small contact area under high pressure. This is gouging.

Just a thought but diamond crusted stone wheels rotated to create the scoop marks. Is there any evidence of diamond dust?

We used diamond coated steel blades much thinner than the scoop marks but what if it was a pole with many diamond crusted wheels and water was used to power it and remove dust from the grinding like a water wheel. Just spitballing.

According to archeologist, the Egyptians did not have diamonds.

The predynastic lost technology was fire. The scoop marks are where hot coals were placed on the granite and left to cool. Then the granite was hit and turned the granite to powdered dust. The resulting scoop MARK is actually how deep the heat went. It changed the crystalline structure of the red granite.

Sincerely,

Harold Martin Fritz

Anyone actually thinking they did this with sticks and stones. some people are to scared to actually consider there was once a civ that was far more advanced than we are today. earth has never been smashed before. its been perfect since cave man days.

All these crackpot theories. And no one has made a small one yet.

even the Egyptians say they found the pyramids, and that they go back 40k years.

we cant move these massive stones. it breaks physics, and if you think its done with rolling them on logs. I would advice you to redo 1st grade mathmatics

Breaks the physics that the general population is taught! That physics is on average a century out of date. You can trust me on that.

Hi – I have a picture of you sitting in the trench on the side of the obelisk. If you want a copy, let me know. I was on the tour with you, Yousef , Ben and the 35 others. I might have some others as well. Gerret

Yes, send message from the contact form.

What about sandblasting?

With enough solar power and freely available sand nearby, it could potentially be a lot easier and cheaper to move tubes around and have high pressure air do the cutting.

This would save the hassle of bringing water in for cutting instruments, and the precision of those aren’t really needed for this type of quarrying, as moving a machine with a blade large enough to make those cuts would be cumbersome in and of itself.

Sandblasting would also explain the smooth walled tube drill straight into the rock.

The uneven “scoops” don’t make sense for a traditional pouding/grinding/drilling machine, as they are too inconsistent one to the next.

But they make perfect sense for a squarish aperture sandblaster, as the dwell time and air pressure would inevitably vary a bit, causing pseudrandom marks like these.

This would explain the straight cuts down the sides, but scoop marks on the “point of impact” as well.

A non-contact method would be great, as it would be easy to move the blasted material as well.

Just a thought, we use sandblasting all the time today to etch and surface marble.

Why not use it to quarry? Save water and only need the plentifully available nearby sand…

This would make it useful anywhere in the desert, unlike water-dependent systems.

Although, it may not have been a desert back then, so… who knows.

But how to create such high air pressure?

We don’t even know how they created the pyramids, precision crafted 10m tall statues (perfect symmetry, perfectly polish surfaces), how they ran saws (there are saw cuts in the Cairo museum and on the promenade stones at the great pyramid) and ran tube drills through granite.

There are so many precisely manufactured elements in the oldest archiecture (the ancient stone vases which are so thin they are transparent, yet perfectly symmetrical through heterogenous rock – which is almost impossible).

If we only just now have the abilities required to machine some of these things they created thousands of years ago, we have no idea what they really possessed in terms of capabilities.

It would make perfect sense to use wind and sand to blast in that area.

Great question, next question? 😀

Sandblasting, at least today, is for fine work. Not enough mass and power for more.

Water though, like water-jet, or possibly water with sand, would be more effective.

Dang, wrote a whole message and forgot validation fields.

To summarize: particle blasting (ion mills, sandblasters, plasma cutters) all have similar cutting patterns to what is seen at the Aswan Quarry.

If we look at concussive measures, like jackhammer, or piledriving styles, we should see linear tool marks on the walls of the rock being drilled into, given the linear motion of the machines.

We don’t see any evidence of that.

So, given the evidence we do have and that we don’t… I just say this looks like that (those marks look like sandblasting, or particle blasting). How they would do that, I have no idea. I (we) also have no idea how they created the pyramids, or moved those massive stones such lengths… Or how they made perfect vases out of heterogeneous stone.

No idea.

Occam’s razor just provides logical conclusions, not conclusive answers.

How the scoop marks were made. There are holes around the obelisk to put uprights for a gantry. First you build a high gantry with a grid at the top, so that you can drop the dolerite balls through the grid. The balls will hit the same spot every time, you clean out powder and send the balls back up the gantry to start again. You use gravity to do the work. The only work is retrieving the balls and sending them back up the gantry.

The trench around the obelisk needs to wide enough to have an angle for a shoot or a board to give the balls direction to undercut the obelisk. The balls when sent down an angled shoot will hit in front of the shoot then hit the bottom and ricochet to front which will undercut the obelisk.

Thanks. This sounds like a very plausible explanation.

I think they they used a lens or a curved mirror to focus sunlight into a focal point to heat the granite.🤔 Just like you can burn paper with a magnifiyng glass, curved mirrors or multiple mirrors focused on one focal point can heat the material tremendously. the heat is absorbed into the granite and by quickly cooling it with water the quenched granite will crumble. After that you chip the brittle material away with the dolorite pounding stones until you reach hard granite again. Once the area is worked the lens or mirrors are focused on the next area which can create the dips in the rock. It doesn’t cost any fuel for heating, just sunlight which is plenty in Egypt.

The scoopmarks are often deeper in the middle and that is because most heat is absorbed in the middle of the focal point. Adjusting the focal point and heating time can make deeper or les deeper scoopmarks. I also noticed some scoopmarks are in a row under an angle, these can be explained by rotating the device from one point.

To heat up the part underneath the obelisk they could use mirrors under a 45° degree angle.

Have you read the book from Marcell Foti “The Natron Theory”? I think this guy got something there….it does make a lot of sense! Ok, there are still lots of questions but, to me his ideas seem the most logical.